The technical constraints and financial consequences resulting from the need to retro-fit an effective Explosion Protection System into an existing process plant were well illustrated by a Dairy Industry project recently evaluated by IEP Technologies. The customer, one of North America’s leading dairy processors, identified the local plant safety regulations and the requirement to install explosion protection for a Spray Drying Process at their powdered milk plant.

Spray Drying is at the heart of the manufacturing process for powdered milk, and it is in this operation that the major risk of industrial explosions exists. As with many industrial processes involving loose solid materials and ingredients, combustible dust particles are produced during manufacturing - in the case of powdered milk, most commonly in the Spray Dryer where the moisture is evaporated from the liquid milk. These dust particles have the capacity to explode when suspended in adequate concentration and subjected to an ignition source such as excessively hot material buildup on surfaces, friction, uncontrolled electrostatic discharges and more. Although these risks are normally mitigated through good design, engineering and operational safety controls, the potentially devastating consequences can never be completely eliminated therefore robust protection measures are always required to safely deal with the resulting rapid pressure rise and explosive effects.

IEP Technologies had previously supplied this customer with an explosion protection system for a very similar process in a new installation. In the previous application, discussions started early in the project design phase where it was possible to recommend layout changes to enable the use of rupture style vent panels for protection of the drying chamber itself. These took the form of siting the Spray Dryer in an external location, enabling explosion relief panels to be installed with vent ducts to direct the flame and associated products of an explosion out of the building to a safe place where operating personnel or equipment would not be in danger. However, in this more recent project, the plant was already in place, with the Spray Dryer situated in an internal location, therefore the explosion venting method was neither a practical nor safe option.

The requirements in respect of Occupational Health and Safety state that “every blower, conveyor, transfer or processing system for pulverized combustible dust and any other suspended matter presenting a fire or explosion hazard must be designed, built, installed, used and maintained in compliance with [several NFPA explosion protection standards], or with the standard applicable at the time of the installation of the system”. Drawing on their engineering knowledge and thorough understanding of all relevant international standards, IEP engineers consulted NFPA 69 (Standard on Explosion Prevention Systems), and particularly chapter 5 which provides the flexibility to use a “performance-based design option”. One methodology covered in VDI 2263 Part 7 within this category is known as “volume reduction” which permits de-rating of Kst and protected volume reduction in conditions of low dust concentration, assuming certain tests have been conducted and a specific dryer configuration is used. Furthermore, the performance-based design must be prepared by a person with qualifications acceptable to the authority having jurisdiction. Put simply, this enables a partial volume of the dryer to be used for the purpose of calculating the number of explosion suppressors required to protect the equipment, typically resulting in a reduced capital outlay for the plant owner.

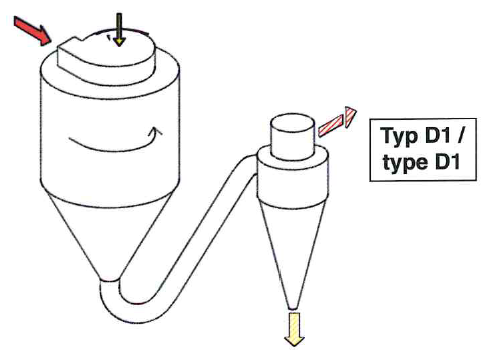

All of the following conditions must be met to allow for partial volume protection in accordance with VDI 2263 Part 7 as well as a type D1 configuration:

• No hybrid mixtures involved, i.e. No organic solvents or essential oils.

• The dissociation temperature of the product is more than 50°C above the maximum

temperature limit for the spray drying process.

• Average dust concentration < LEL (at operating temperature).

• There is no back-feed/return loop of fine product into the spray drying tower.

• Product feed is only from the top.

• Hot air inlet is only from the top third of the tower.

• In all other cases the total free volume of the drier must be assumed as the explosible volume

The dryer configuration and operating conditions did not meet all of the qualifications as listed in the VDI Volume Reduction requirements, so IEP concluded that the reduced volume technique was not applicable in this case and the total free volume of the dryer must be assumed as the explosible volume.